Aluminum-magnesium Castable

Castable refractories consisting mainly of alumina and magnesium oxide, including aluminum-magnesium castable with chemical bonding (water-glass bonding), hydration bonding (pure calcium aluminate cement bonding), and condensed bonding (silica micropowder plus magnesium oxide powder bonding).

According to the different quality of raw materials used can be divided into: ordinary aluminum - magnesium castable; Ordinary high aluminium spinel castable; Aluminium-magnesia castable; Alumina - spinel castable.

(1) ordinary aluminum-magnesium castable is composed of super or first grade high-alumina aggregate and powder (Al2O3 ≥ 85%) and sintered magnesia powder (MgO ≥ 92%). Early (1980s) common aluminum-magnesite castable was made of water glass solution as binder for ladle lining with good slag resistance and suitable for die cast steel lining. However, because this kind of castable contains Na2O brought in by water glass, its high-temperature load-softening temperature is low and its resistance to slag erosion is poor, so it is not suitable for the lining of continuous casting ladle and refined ladle outside the furnace. Therefore, silicon oxide micro powder and magnesium oxide fine powder are now used as binders, resulting in binding by condensation.

1) the mechanism of condensation and binding is that SiO2 powder and MgO powder first form sol in water. In aqueous solution, SiO2 colloidal particles are negatively charged, and MgO particles will slowly release Mg2+ ions during hydration. When Mg2+ ions are adsorbed by negatively charged colloidal SiO2 particles and the surface of SiO2 colloidal particles reaches the isoelectric point, SiO2 particles will coagulate, resulting in binding. This type of agglomerated castable avoids the adverse effect of the above mentioned water-glass combined castable bringing into Na2O, thus improving the high temperature service performance of castable. Now, water-glass combined aluminum-magnesium castable is widely replaced as the lining of medium and small continuous casting ladles.

2) the common aluminum-magnesium castable ingredients with agglomerating combination are: aggregate is 20~10mm,50%; 10 ~ 5 mm, 10%; Less than 5mm, 40% of the high alumina hot material particles, powder is made up of super high aluminum clinker powder (less than 0.074mm), sintered magnesia powder (less than 0.074mm) and silica micropowder (less than 1xm). The ratio of aggregate to powder is generally (65~70) :(35~30). However, the addition of magnesia powder and silica powder should be strictly controlled in the mixture ratio of powder (matrix). The addition amount is determined by test according to the performance requirements.

3) the general physical and chemical properties of agglomerated aluminum-magnesium castable are as follows: chemical composition: w(Al2O3)68%~76%,w(MgO)6%~8%, volume density after drying (110℃, 24h) 2.80~2.95g/cm3, compressive strength 30~50MPa, bending strength 5~10MPa, 1500℃, volume density 2.70~2.90g/cm3, compressive strength 40~80MPa, bending strength 8~12MPa, line change rate ±0.5%. This castable is used as an integral lining of a continuous casting ladle. The service life fluctuates with the different service conditions, generally in 80~120 times.

(2) ordinary high aluminum-spinel castable is prepared with super (or first class) high bauxite aggregate and powder, bauxite based sintered spinel aggregate and powder. There are two ways of combining castable: hydrated (cement) combined castable and agglomerated combined castable.

1) the hydrated castable matrix is composed of sintered spinel powder, superfine aluminum clinker powder (or corundum powder), pure calcium aluminate cement and a dispersant. The addition amount of pure calcium aluminate cement should be strictly controlled, which is generally 5%~8%.

2) the agglomerated castable matrix is composed of sintered spinel powder, extra-high aluminum clinker powder (or corundum powder), sintered magnesia powder, SiO2 micro powder and micro dispersant. The content of sintered magnesia powder is generally 6%~8%, and the content of SiO2 powder is 2%~3%.

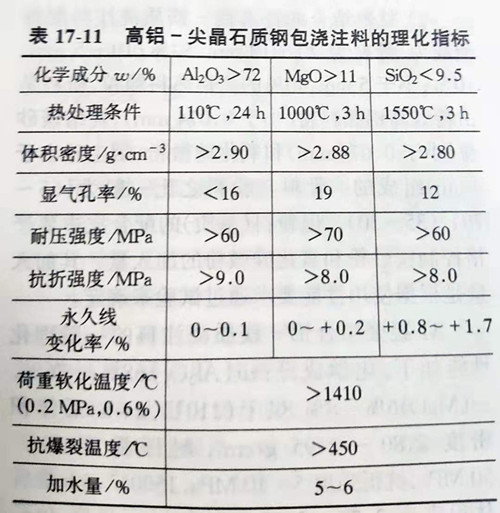

The particle size composition of ordinary high aluminum-spinel castable aggregate can be adjusted according to Andreassen's particle size distribution equation. The particle size distribution coefficient q is controlled between 0.26 and 0.35. The content of spinel was between 10% and 15%, some of which were added with 3~1mm particles and some with powder less than 0.074mm. The chemical properties of the general high alumina - spinel casting are shown in table 17-11.

The characteristics of this kind of castable are: the strength difference between medium temperature (1000℃) and high temperature (1550℃) is small. It is helpful to overcome structural spalling caused by thermal stress, and its resistance to structural spalling is slightly better than that of ordinary aluminum-magnesium castable. Suitable for medium and small continuous casting ladle lining, middle lining and electric furnace lining.

(3) pure aluminium-magnesia castable, the aggregate of which is white fused alumina, or plate-shaped alumina, or electrically fused high-alumina fused alumina. The powder is composed of corundum fine powder and micro powder, reactive alumina powder, sintered magnesia powder, silica micro powder and dispersant. The test results show that the content of MgO in castable should be controlled at 6%~8%, higher than this range, and the erosion resistance of slag becomes worse. And below this range, the permeability of slag resistance variation, requirement in use by in situ reaction in the combination of generation is given priority to with spinel phase in the matrix, and the purpose of SiO2 powder is to improve the strength of the castable and regulation (control) line rate, because SiO2 powder have promote sintering and reduce by in situ reaction of spinel expansion ratio. However, the addition amount of SiO2 powder should not be too high. When it is too high, the corrosion resistance not only decreases obviously, but also the thermal shock resistance becomes poor.

The particle size composition of pure alumina - magnesia castable can also be controlled by Andreassen's particle size distribution equation. When preparing vibrating forming castables, q value is 0.26~0.35, while when preparing artesian castables, q value is 0.21~0.26. Meanwhile, the corundum powder (powder -al2o3) is best to use the powder with bimodal particle size distribution, and efficient dispersant should be used.

The general physical and chemical properties of this type of alumina - magnesia castable are as follows:

1) chemical composition: w (Al2O3) 89%~91%,w (MgO) 6%~8%.

2) after drying at 110℃ and 24h, the volume density was 2.95~3.00g/cm3, the flexural strength was 7.5~ 8.5mpa, and the apparent porosity was 18%~20%.

3) after firing at 1500℃ for 24h, the volume density was 2.9-2.95g /cm3, the flexural strength was 12-16mpa, the apparent porosity was 20%-23%, and the linear change rate was + (1.0%~1.5%).

Pure aluminum-magnesia castable, generally used as the integral lining below the slag line of large ladles (> 100t), with a service life more than one times that of ordinary aluminum-magnesia castable, can also be used as the lining of other high-temperature furnaces, containers and flow tanks.

(4) pure alumina-spinel castable is made of fused or sintered corundum or plate-shaped alumina as aggregate. The powder (matrix) is composed of pure synthetic spinel powder, powdered alumina micropowder, reactive aluminum oxide powder, pure calcium aluminate cement and dispersant. This type of castable is a low cement-bonded castable with a content of 3%~8% (quality).

(5) the characteristic of this kind of castable is that magnesia is not added, and MgO is added in the form of spinel, so there is no in-situ reaction between MgO and Al2O3 in use to produce spinel and produce obvious volume expansion effect. The change rate of residual line is small and the volume is stable. However, the reaction of spinel with Al2O3 to produce cationic vacancy aluminum-rich spinel and calcium aluminate cement with Al2O3 to produce calcium hexaaluminate (CaO·6Al2O3) will lead to a micro volume expansion effect.

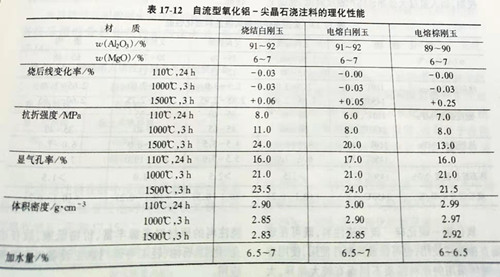

The grain size composition of castable with pure alumina - magnesia castable is similar, according to the performance of construction (vibration type or gravity type) requirement to determine particle size ratio, coefficient of vibration model for particle size distribution of q value of 0.26 ~ 0.35, and their type of q = 0.21 ~ 0.26, can also according to the following scope to make up: 35% ~ 50% greater than 1 mm, 1-0.045 mm is 15% ~ 30%, 35% ~ 40% less than 0.045 mm. Artesian castable with artesian value greater than 180mm can be obtained in this range. The physical and chemical properties of typical artesian alumina - spinel castable are shown in table 17-12.

Pure aluminum-spinel castable is mainly used as the integral lining of large (> 100t) ladle with a service life of up to 200~260 times. It can also be used to make the liner of high power and ultra-high power electric furnace cover, as well as the liner of ladle gas plug, argon blowing or powder spraying.