Raw Material of Unshaped Refractory

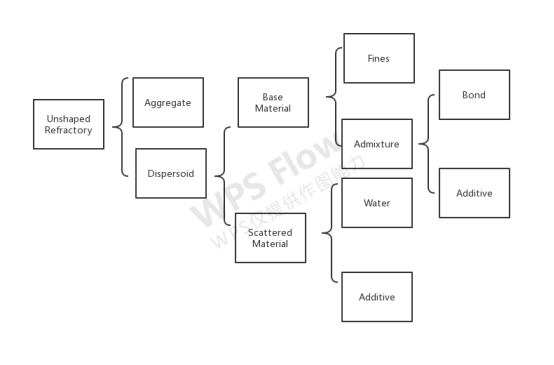

The raw materials of unshaped refractory are divided into refractory aggregate, refractory powder, binder and admixture. Using different properties of raw materials, can be prepared into different performance, temperature and range of use of unshaped refractory. Modern shapeless refractories generally adopt composite raw materials to give full play to their respective characteristics in order to obtain the best physical and chemical properties and improve the service life of products. The material composition diagram of unshaped refractory is as follows:

In the unshaped refractory, the content of refractory aggregate is generally 63-73%, which plays the role of skeleton and can significantly affect its performance. The refractory powder dosage is 15%-37%, which plays the role of filling the gap of aggregate and improving the construction and ease. Some refractory powders, such as clay and superfines , are good binders. The ideal particle size is that the gap caused by coarse aggregate is filled by fine aggregate, and the gap between the two is filled by refractory powder to achieve the maximum packing density, so as to obtain the best performance.

Refractory aggregate is divided into coarse aggregate and fine aggregate. Generally, coarse aggregate is coarse aggregate whose particle size is larger than 5mm. The particles of 5mm-0.088mm are called fine aggregate. The critical size of aggregate is determined according to different construction methods, as shown in table 2-1. At present, the critical particle size of refractory aggregate tends to decrease, generally with 8mm or 5mm, pump feed for 3mm.

|

moulding method

|

vibration |

spraying |

ramming |

Pumping material |

|

critical particle size

/mm |

>10 |

10-5 |

10-5 |

5-3 |