Zircon Products

Zirconium refractory products are zirconium oxide, zirconium quartz as the main raw materials for the production of refractory products. According to the composition can be divided into zirconia products, zirconium products, zirconium corundum products and zirconium mullite products. According to the production process can be divided into sintering products and casting products.

Zircon products

Zircon as the main raw material, adding the right amount of sintering additives (the most common is refractory clay) made of products.

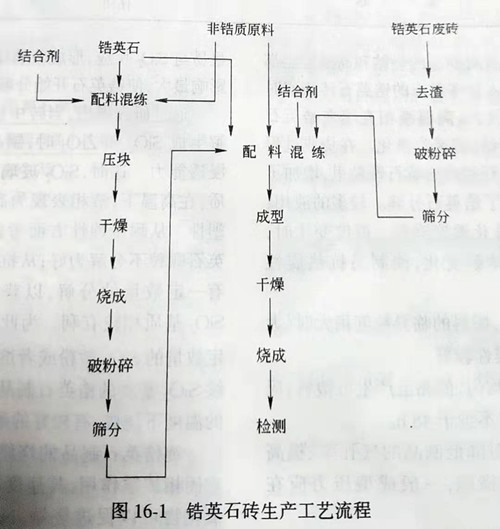

Due to the zircon raw material itself is not plastic and decomposition at high temperature, so in the production of the binder, particle size ratio and firing conditions must be adopted to adapt to the process measures, as shown in figure 16-1 zircon products production process.

High quality zirconium should be chosen as the raw material for brick making, the mass fraction of ZrO2 is more than 65%, strictly control the impurity component R2O in zirconium, because R2O will not only reduce the decomposition temperature of zirconium, but also affect the amount and viscosity of the glass phase formed after decomposition.

Zircon raw material particle size is very fine, direct brick, technology difficult. In order to adjust the particle composition of the ingredients and reduce the burning shrinkage, zirconium is pre-synthesized clinker. Before the synthesis of clinker, it is best to grind zirconium stone fine, in order to promote sintering, lower sintering temperature, and can increase the plasticity of clay. Usually more than 80% of the particles are ground to less than 0.063mm. Such raw materials can be made low water absorption, high volume density clinker.

When soft clay is chosen as binder, clay with high plasticity, high fire resistance and low sintering temperature should be selected. For example, Al2O329%~32%,SiO2 48%~50%, calcination 15%~16%, fire resistance 1730~1750℃, plasticity index 1.95~2.96, sintering temperature around 1300℃ soft clay.

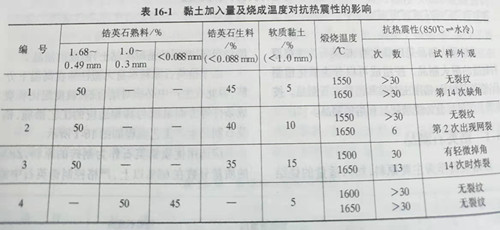

With the increase of the amount of clay, zircon brick significantly lower refractoriness, refractoriness under load, also increased from 5% to 15%, for the amount of clay refractoriness of products from 1750 ℃ to 1680 ℃, refractoriness under load reduced from 1700 ℃ to 1600 ℃. The amount of clay and sintering temperature against the effects of thermal shock resistance are shown in table 16-1. Reduce the amount of clay, is conducive to the improvement of the thermal shock resistance of zircon brick, full part in clinker than in raw products with higher thermal shock resistance.

The addition of clay has great influence on the sintering and high temperature properties of products. Zircon bricks with more clay are fired to form a large amount of high temperature liquid phase, which is filled around zircon particles to promote sintering and densification. During the sintering process, the liquid phase permeates into the cracked zircon particles, adding a new reaction surface and promoting the zircon decomposition. More liquid phase, so that the refractoriness and softening temperature under load decreased. When the temperature changes, the corresponding large volume changes, so that the thermal shock resistance of the product becomes poor.

The practical application shows that when the critical particle size of the batching is a little larger (more than 3mm), its thermal shock resistance is better.

In order to make the mud material moisture uniform, so that the clay can produce plastic, should be trapped, trapped time is not less than 48 hours.

Increasing molding pressure is an effective measure to reduce the porosity and increase the volume density of products. Generally, the molding pressure should be above 85MPa.

Zircon products firing temperature is 1550~1650℃, in order to avoid a large number of zircon decomposition, zircon brick firing temperature should be controlled below 1600℃.

When fired, zircon decomposes at high temperatures. Pure zircon began to decompose slowly at 1540℃ and rapidly at 1700℃. Factors affecting zircon decomposition include impurities in the raw material, particle size, heating temperature, holding time, furnace atmosphere, heating speed and cooling speed. And SiO2 strong reactivity of oxide, impact on the decomposition of zircon, and according to the periodic table Ⅰ clan st13 Ⅱ clan st13 Ⅲ family order, namely the alkali metal oxide (Na2O, K2O) most likely to react with SiO2, glass phase formation, the impact on the decomposition of zircon, reduce the temperature of the zircon began to break down.

Through the study, when about 30% of zircon in the brick decomposition to produce SiO2 and ZrO2, the product has a high resistance to slag penetration. At this time, the SiO2 glass phase has formed a continuous matrix, at high temperature, the liquid phase is high viscosity, and the brick thermoplastic. Zircon particles in zircon bricks do not decompose well in terms of corrosion resistance. In terms of resistance to slag penetration, a certain amount of decomposition is preferable to obtain continuous high viscosity SiO2 matrix. To this end, a certain amount of SiO2 powder or fused quartz powder is added in the process to prepare zircon products with continuous SiO2 matrix, which can be fired at a lower temperature, with better durability.

The sintering of pure zircon products is difficult, and the rate is very slow under high temperature by solid phase diffusion. Adding some oxides can promote sintering. Na2O, K2O, MgO, CaO, B2O3 and other oxides can promote sintering very effectively, but also significantly promote zircon decomposition. TiO2, P2O5, Fe2O3, BeO, Cu2O and other oxides can promote the sintering of zircon products, but not the decomposition of zircon. Therefore, TiO2 and P2O5 can be used as sintering additives for zircon materials.

The zirconium raw material (containing ZrO2 64%~65%) is ground to a particle size of less than 0.06mm 82%, with 7% starch paste (powder: water =1:7) as binder, forming pressure 85MPa, water forming body 4.5%~5.5%, the highest firing temperature 1600℃, heat preservation 2~3h, the zirconium raw material with water absorption rate of 4%~6%.

With zirconium clinker as coarse particles (particle size 1.5-0.5mm), ball milling powder (particle size less than 0.06mm) and soft clay (particle size less than 0.5mm) as fine powder, batting, mixing and binding materials for 48h, forming pressure 85MPa, residual moisture of brick drying ≤ 3%, bulk density of semi-finished products ≥ 3.1g/cm3, sintering temperature 1550~1600℃, thermal insulation 3~4h, porosity rate of preparation ≤ 24%, The bulk density ≥ 3.2g/cm3, the compressive strength at room temperature is 50~70MPa, the softening temperature under load (0.2MPa) is 1510~1630℃, containing ZrO2 56%~60% zirconium products.

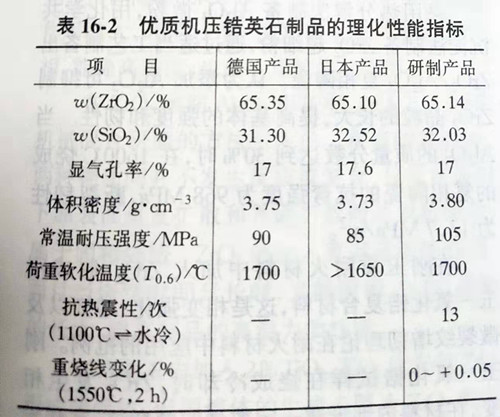

The physical and chemical properties of high-quality machined zirconium products are shown in table 16-2. The process consists of grinding zirconium sand (less than 0.088mm, 97%), synthesis of clinker, then crushing into 5~3mm, 3~1mm,1~0mm, adding a certain proportion of additives (TiO2+Al2O3+MgO) in the matrix, about 0.8%~1.5%, adding 5%~25% zirconium sand, and sintering at 1550~1650℃.

Zircon products of refractoriness and high refractoriness under load, small thermal expansion rate, good steel slag erosion resistance and thermal shock resistance, once the ladle lining materials is widely used, such as baosteel, early production of 30 t ladle, using wax stone, brick, life expectancy of 38 times, and the use of imported zircon brick life over 90 times, but the price of zircon brick more expensive, in the later of ladle refractory materials, has been replaced by high aluminum refractory.

Zircon brick for ladle lining is used, in most cases is slag brick through the stomata to internal penetration, and react with the decomposition of zircon particles formed metamorphic layer, and from the metamorphic layer spalling occurs, in order to improve the durability of zircon brick, must improve the penetration resistance of brick, through research that joining pyrophyllite, made of zircon brick of pyrophyllite, can make the stomatal ultra-micronization model.the, inhibit slag penetration.

In the production of zircon bricks for ladle, synthetic zircon clinker is used as particles, and zircon Al2O3/SiO2 mixed powder is used as fine powder. When Al2O3/SiO2 is relatively low, a high-temperature liquid phase with high viscosity can be generated, which improves its resistance to slag penetration.

The high temperature strength of the product can be increased obviously by adding electric melting Al2O3. By adding Cr2O3 to the matrix, the brick with dense structure can be made.